Mitsubishi Electric has marked the 30th anniversary of its factory

in Livingston, Scotland, an advanced facility for the manufacture of

heat pumps as the nation looks to reach net zero.

Established in 1993, the Livingston plant has been

manufacturing air conditioning units for 30 years and producing heat

pumps for installation across the UK and Europe since 2009.

Currently, it is the largest heat pump manufacturer in the UK,

employing approximately 1000 people and helping to support investment in

Scotland's green economy and the wider transition to low-carbon

heating.

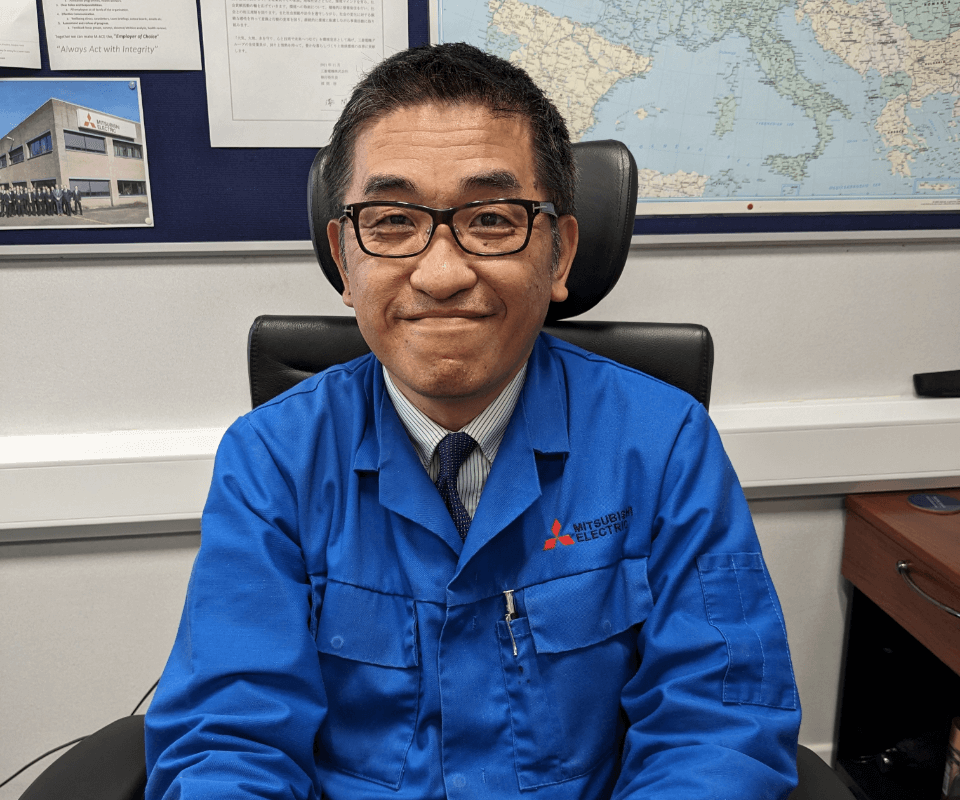

To mark the occasion, Mitsubishi Electric

hosted an anniversary event at the factory on 6th July 2023. Key

government and industry figures attending included Patrick Harvie,

Minister for Zero Carbon Buildings, Hannah Bardell, MP for

Livingston, and Tadashi Fujiwara, the Consul General of Japan in

Edinburgh.

Continued investment by Mitsubishi Electric,

together with support from Scottish Enterprise, has seen the

Livingston factory expand and grow in heat pump production.